Enroll For ZED/LEAN/ISO

Enroll For ZED/LEAN/ISO

Enroll For ZED/LEAN/ISO

Enroll For ZED/LEAN/ISO

Driving India’s Manufacturing Transformation with Creative Impex

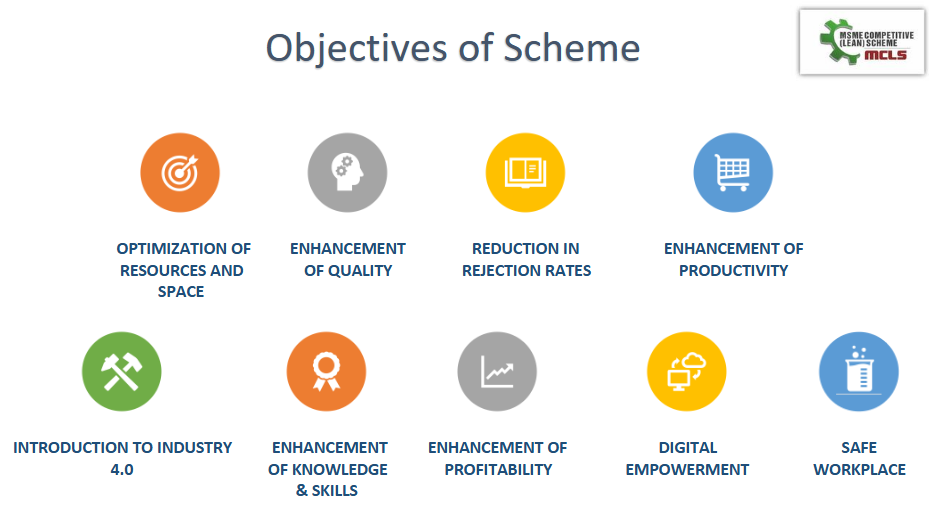

At Creative Impex, we believe that true competitiveness begins with continuous improvement. Through the LEAN Manufacturing Competitiveness and Lean Scheme (MCLS), we are helping Indian enterprises transform into efficient, agile, and globally competitive organizations.

The LEAN Scheme, initiated by the Government of India, empowers manufacturing units to systematically eliminate waste, optimize processes, and build a culture of excellence and innovation. It is not just a cost-cutting exercise — it’s a complete transformation journey toward higher productivity, sustainability, and profitability.

As an active facilitator under the LEAN MCLS initiative, Creative Impex works closely with industries across India to implement Lean practices that bring measurable and lasting results.

We go beyond consultancy — our team of experts handholds each enterprise step-by-step, ensuring every process, every team, and every operation aligns with the Lean philosophy of “Continuous Improvement and Zero Waste.”

Awareness & Orientation Programs: Introducing Lean principles and their real-world impact.

Cluster Formation: Grouping industries with similar operations for shared learning and cost-effective implementation.

Diagnostic Assessment: Identifying inefficiencies, bottlenecks, and improvement opportunities.

Our goal is to ensure that every individual, regardless of their location or economic status, has the opportunity to lead a healthier, happier life. Ensuring everyone has access to essential healthcare services, we provide medical support, preventive care, and health education to improve community well-being.

Embracing LEAN with Creative Impex helps your organization achieve:

A systematic approach to organize and maintain a clean, efficient, and safe workplace.

A culture of ongoing, small improvements that enhance processes and productivity.

A visual tool to identify and eliminate waste across the entire process flow.

A proactive system to maximize equipment efficiency and minimize downtime.

Tools to improve workflow and reduce setup time for faster, smoother production.

Regular Reviews & Progress Tracking: Measuring results, reporting impact, and ensuring sustainability.

Every stage is guided with precision to ensure that your enterprise achieves visible gains in quality, productivity, and profitability.

LEAN isn’t just a project — it’s a mindset that transforms how industries think, act, and grow.

Creative Impex – Partnering India’s Growth Story

With a team of trained facilitators and industry experts, Creative Impex is driving the LEAN revolution across India’s manufacturing sector.

Our mission is to help every enterprise — big or small — embrace operational excellence, strengthen competitiveness, and contribute to India’s vision of becoming a global manufacturing leader.

Together, let’s create industries that are Lean, Clean, and Globally Competitive.

📞 Connect with Creative Impex today to begin your Lean Transformation Journey.

Let’s shape the future of Indian manufacturing — one efficient process at a time.

Join Us

Join Us